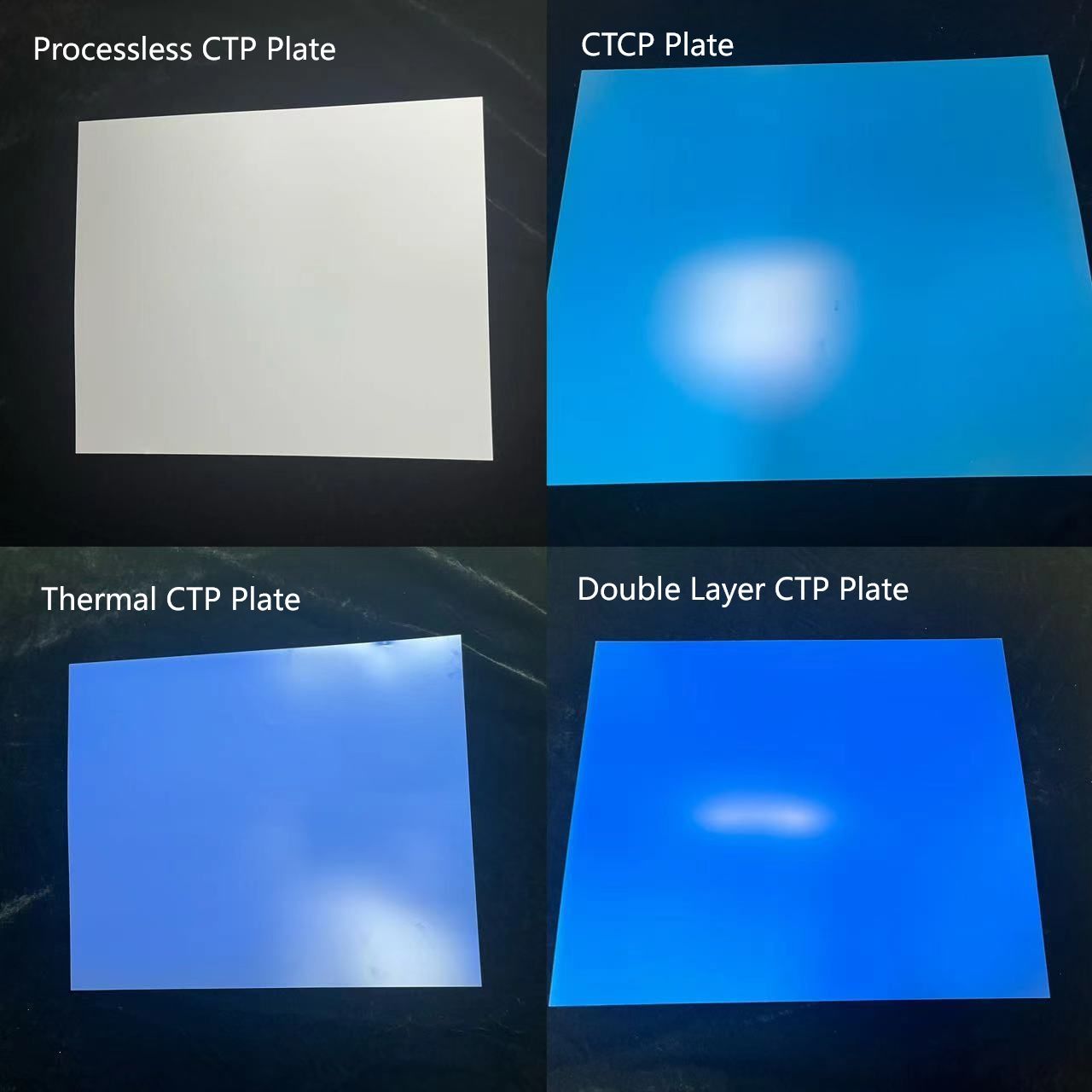

Aluminum printing CTP plates are designed to meet the high demands of modern printing. The core material aluminum combines lightness, strength and excellent thermal conductivity, making it ideal for precise image reproduction. These boards usually have a multi-layer structure, including the following layers:

Base Layer: High-quality aluminum plate that provides the structural foundation.

Grained Layer: This layer increases the surface area and ensures better adhesion of the photosensitive coating.

Anodized Layer: Improves durability, abrasion and chemical resistance.

Photosensitive Coating: The critical layer that reacts to laser exposure to form the image to be printed.

The granulation and anodizing processes are critical to improving the performance of the board. Granulation is usually achieved by mechanical or electrochemical methods, creating a rough surface that enhances ink adhesion. Anodizing involves an electrochemical process that increases the natural oxide layer of aluminum, providing additional protection and extending the life of the sheet.

The quantitative indicators of aluminum substrates for CTP and PS mainly include the chemical composition of the aluminum substrate, shape and dimensional accuracy, mechanical properties at room temperature, unevenness and surface roughness, etc.

The alloys currently used in the CTP version are mainly 1050, 1060, 1070 and self-made alloy grades adjusted with trace elements on this basis, such as 1052, etc., which are consistent with the alloy grades used for the aluminum substrate of the PS version.

Advantages of aluminum printing CTP plates

1. High resolution and precision: The aluminum surface is smooth and uniform, enabling high-resolution image reproduction, which is essential for producing clear and detailed prints.

2. Improve printing quality: The high resolution and precision of aluminum CTP plates raise the standard of printing quality, benefiting industries such as publishing, packaging and advertising.

2. Durability: Aluminum plates are strong and durable and can withstand the rigors of the printing process, including multiple runs and handling.

3. Cost Savings: The longevity and reusability of aluminum plates can lead to significant cost savings over time, making them an economically viable option for printers. While the initial cost of aluminum sheets may be higher than some alternatives, their longevity and ability to produce high-quality prints reduces overall costs in the long run.

4. Improve production efficiency: The efficiency of the CTP process can speed up plate production, reduce downtime and increase overall productivity.

5. Environmental benefits: The CTP process does not require chemical treatment, reducing the impact on the environment. Additionally, aluminum is recyclable, contributing to sustainability.

Aluminum printing CTP plate production process

The production of aluminum printed CTP plates involves several detailed steps:

Selection of Aluminum Plate: High purity aluminum plate was chosen for its consistency and quality.

Granulated: Aluminum sheets are granulated to create a textured surface. This can be done mechanically or electrochemically, depending on the desired properties.

Anodized: Granular sheets are anodized to create a strong, corrosion-resistant surface.

Coating Application: Apply the photosensitive coating evenly to the anodized aluminum panel. This coating is critical to the plate's ability to accurately capture and transmit images.

Inspection and Quality Control: Each plate is inspected to ensure it meets strict quality standards, ensuring consistent performance in printing applications.

Aluminum-printed CTP plates represent a significant advancement in printing technology, with numerous advantages that increase print quality, efficiency and sustainability.