Packaging is one of the three major application fields of aluminum. Aluminum packaging has become the best choice of efficient packaging materials in dealing with plastic waste pollution, reducing resource consumption, ensuring food safety, reducing carbon emissions and some other environmental aspects.

What aluminum is used for packaging?

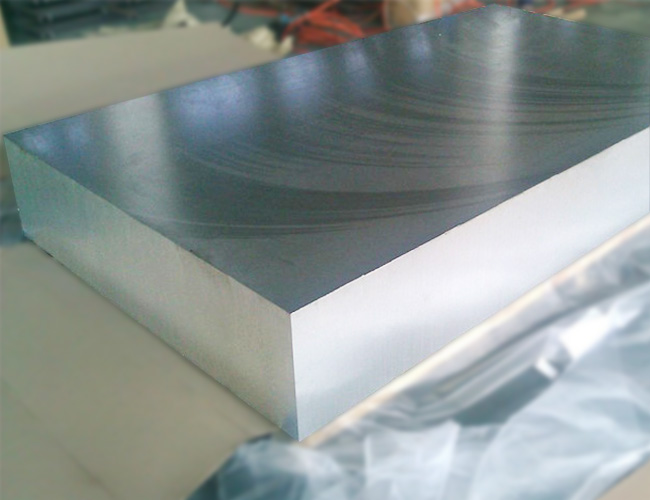

Aluminum, as a packaging material, generally uses aluminum plates, aluminum blocks, aluminum foils, metalized film, aluminum discs, aluminum sheets, aluminum coils, aluminum strips etc.

- Aluminum plate is usually used as can making material or cover making material.

- Aluminum blocks are used to make cans for extrusion forming and thin reduction and deep drawing forming.

- Aluminum foil is generally used for moisture proof inner packaging or composite materials and soft packaging.

Why is aluminum good for packaging?

- Aluminum packaging materials have excellent mechanical properties, high strength, safety and reliability. And they are easy to store, carry, transport, load and unload.

- The water vapor permeability of aluminum is very low and it is completely opaque, which can effectively avoid the harmful effects of ultraviolet rays.

- Its gas resistance, moisture resistance and fragrance protectiveness greatly exceed other types of packaging materials such as plastic and paper.

- The aluminum packaging can maintain the quality of the goods for a long time and prolong the service life of the goods. This is particularly important for food packaging.

- Aluminum packaging materials are easy to print and decorate. This can make the appearance of the goods gorgeous, beautiful and easier to sell.

- The aluminum packaging material can be recycled and reused, so it is an ideal green packaging material.

Different application forms of aluminum packaging

Aluminum packaging includes aluminum foil soft packaging, aluminum cans, aluminum foil containers, aluminum bottles, aluminum covers, aluminum tubes and aluminum aerosol cans, etc.

Following is a brief introduction to the main applications:

Flexible packaging aluminum foil

Aluminum foil, as the packaging material, is mainly used for food packaging, pharmaceutical packaging and beverage packaging.

Foil Food Packaging

The main raw material for food packaging aluminum foil is 1 series, 3 series and 8 series aluminum alloy products, mainly include 1060, 1100, 3003, 8011, 8021 etc. And the tempers are also different according to the different requirements for food packaging aluminum foil. Common tempers are H14, H16 and H18.

Aluminum foil for Take-Out Containers

Aluminum is a common material for Take-Out Containers

Take-Out Containers are widely used and are one of the most effective and economical food packaging methods. Aluminum foil containers have many advantages and a wide range of applications. They can improve the freshness of food and extend the shelf life. At the same time, they will not absorb water or oil, and can be heated directly without producing harmful substances. They meet the fast-paced lifestyle of modern people and comply with international environmental protection. trend.

8011 alloys also began to be used in aluminum foil containers

Later, in order to reduce costs, 8011 alloys also began to be used in aluminum foil containers. The reduction in cost has led to the further promotion and use of aluminum foil as a container material, but at the same time, the strength of the container is significantly lower than that of 3003 alloy. High-end containers, especially export aluminum foil containers, still use 3003 alloy.

3004 aluminum foil was widely used in aluminum containers

Later, 3004 aluminum foil was widely used in aluminum containers. On the basis of ensuring the low price of 8011 alloy, it also guaranteed the high-strength characteristics of 3003 alloy, and its strength was higher than that of 3003 alloy. It can be said that it has the price of 8011. advantage and strength advantage of 3003.

Pharmaceutical Packaging Aluminum Foil

Safe and hygienic, clean water grade

Pharmaceutical packaging aluminum foil has become a new type of pharmaceutical packaging widely used in the world. Haomei Aluminum is a large-scale manufacturer of pharmaceutical packaging aluminum foil substrates. The 8011 pharmaceutical aluminum foil, 8021 pharmaceutical aluminum foil, and 8079 pharmaceutical aluminum foil produced by the company have undergone strict standards. Pore detection, degreasing process and plate shape control ensure that the produced pharmaceutical aluminum foil can achieve ultra-high sealing performance in the later adhesive compounding process and perfectly protect the quality of pharmaceuticals.

It has been proved by the practice of major pharmaceutical packaging material manufacturers that haomei’s pharmaceutical packaging aluminum foil meets the production requirements and the performance meets the standards.

8011 ptp pharmaceutical foil

8011 aluminum foil is used for pharmaceutical packaging: PTP pharmaceutical aluminum foil, cold stamping pharmaceutical foil, 8011-H18 pharmaceutical packaging aluminum foil, capsule aluminum foil, etc. Advantages: high cup convexity, high aluminum foil strength, and good sealing;

It has excellent moisture resistance, shading advantages and high blocking ability. Strong mechanical properties, good shear and tensile properties, easy to process. It has good corrosion resistance and has a certain ability of stress corrosion cracking. The products produced by haomei are of high quality, with a clean and shiny surface.

8021 cold forming pharmaceutical foil

8021 aluminum foil is one of the key products of haomei Aluminum. The thickness range of production is 0.018mm-0.2mm, and the width can be controlled at 100-1650mm according to customer requirements.

Cold-formed aluminum overcomes the deficiencies of conventional medical PVC hard sheets and PP hard sheets in terms of moisture resistance, gas insulation, light protection, and thermal stability. It is a drug that isolates various gases and blocks light radiation. Blister type material for packaging. It can effectively prolong the shelf life of medicines and can be used as medicine packaging materials in extreme (high/low temperature) environments.

8079 medical aluminum foil

8079 aluminum foil has high strength, excellent elongation and compression performance, and is easy to form. The layout requirements are strict, the layout is flat, the porosity is guaranteed when cutting, and the brushing water can reach the A-level standard. It is not easy to deform under high and low temperature conditions, and has the characteristics of shading, airtight, non-toxic and tasteless. The surface has a silver-white luster, and it is easy to process beautiful patterns and patterns of various colors. haomei Aluminum can produce 8079 aluminum foil of O, H22, H24 temper.

1060 medicinal aluminum foil gasket

1060 aluminum foil is widely used to make gaskets due to its high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. With heat seal to PVC. The appearance is novel and enhances the competitiveness of medicines. Good printing and coloring, rich colors and clear patterns.

Aluminum coil/sheet for beverage bottle caps

Aluminum is a common material for beverage bottle caps

Aluminum beverage bottle caps are made of high-quality special aluminum alloy materials and are mainly used for the packaging of wine and beverages (with or without steam), and can meet special requirements such as high-temperature cooking and sterilization. At present, about 50% of beverage bottle caps in my country use aluminum cap materials. Compared with plastic bottle caps, aluminum bottle caps not only have better performance, but also have low cost, no pollution, and can be recycled

Aluminum coil/sheet base material for beverage bottle caps

Manufacturer type: manufacturer of aluminum coil/sheet raw materials for beverage bottle caps (does not do post-processing such as compounding, printing, gluing, etc., only provides aluminum basic materials)

Thickness: 0.012-0.5mm Width: 100-1600mm Material temper: H13, H14, H16, H18 Application fields: packaging of alcoholic beverages and beverages (with or without steam).

Performance of 8011 aluminum coil/sheet for beverage bottle caps

The aluminum coil pattern is flat, the surface of the board is clean, and the color is relatively uniform;

Hygiene is guaranteed, no spots, no voids; It has good moisture resistance, strong barrier ability and light shading performance;

Excellent mechanical properties, high blast resistance, strong puncture and tear resistance;

Non-toxic and tasteless, safe and hygienic, clean after degreasing;

Water brushing grade A, low ear removal rate, high cup convexity, high aluminum coil strength, and good airtightness After compounding, printing and gluing aluminum coil can be widely used as packaging materials.

8011 H18 cap material

8011 H18 bottle cap material, this temper is mainly applied to stamping shallow caps, and casting and rolling can be used. Its process: cold rolling-coil rolling-stretch bending straightening-slitting-packaging and other processes, does not require annealing treatment, so in the production process, the time period is the shortest, of course, the price is also the cheapest.

8011 H16 bottle cap material

The 8011 H16 bottle cap material process is completed through multiple processes such as cold rolling—foil rolling annealing thickness—annealing—foil rolling finished product—stretch bending straightening—slitting. After the finished roll is produced, it needs to go through multiple processes such as cutting, painting, drying, multiple stamping, and anti-counterfeiting marks, etc., to finally produce qualified bottle cap materials. 8011 H16 bottle cap material is still slightly different in the production process, due to different stretching requirements, there are differences in annealing.