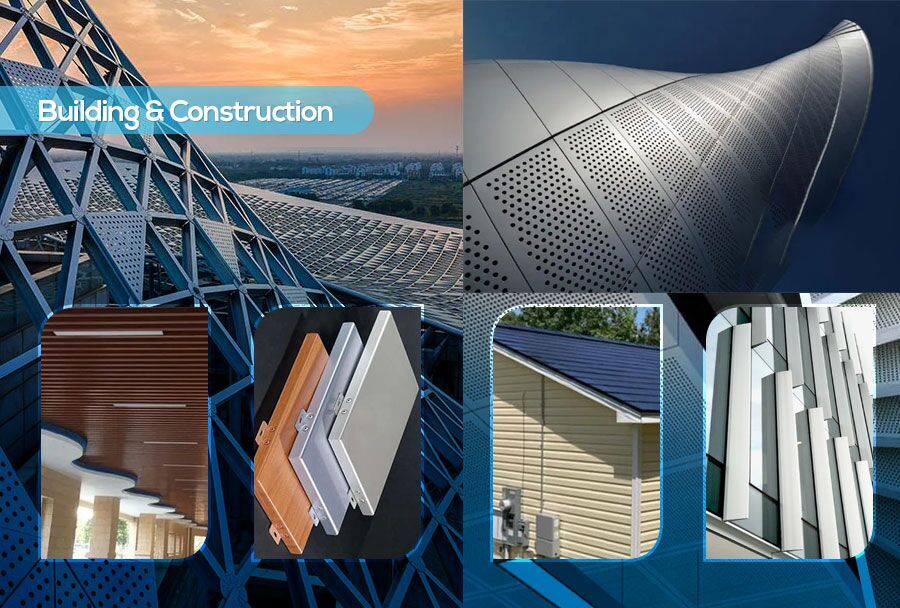

Aluminum alloy has beautiful color, good corrosion resistance, high reflectivity to light and heat, and good sound absorption performance. Various colors can be obtained by chemical and electrochemical methods. Therefore, aluminum materials are widely used in roofs, walls, doors and windows, skeletons, interior and exterior decorative panels, ceilings, suspended ceilings, handrails, indoor furniture, store containers and construction templates of industrial and civil buildings.

Aluminum veneer curtain wall material 3004 aluminum plate

Aluminum is a Common Material for Aluminum veneer curtain wall material

Aluminum curtain walls and aluminum alloy roofs are very common in many buildings, mostly made of 3004 aluminum plates. The wide application of aluminum alloys in the construction industry has played an important role in the development of modern buildings in the direction of comfort, lightness, durability, economy, and environmental protection.

The aluminum veneer curtain wall is not only rich in color, but also economical and of good quality, which is favored by the owners. Aluminum veneer curtain wall is made of high-quality aluminum plate material, which is manufactured through cutting, folding, bending, welding, reinforcement, grinding, spraying and other processes. It is a new type of curtain wall material and occupies a major position in building materials.

Introduction of 3004 aluminum plate for metal exterior

3004 aluminum plate is a relatively common building material, belonging to the AL-Mn alloy, is a widely used anti-rust aluminum, good formability, weldability, corrosion resistance, higher strength than 3003 aluminum plate, usually used for requirements than 3003 Alloy higher strength parts.

3004 aluminum plate is an environmentally friendly material. The exterior wall and roof are made of 3004 aluminum plate. It has the characteristics of high strength, light weight and durability, earthquake resistance and fire prevention, rich color, easy installation, corrosion resistance and long service life. It has been widely used in industrial and civil buildings. , warehouses, special buildings, house roofs, walls and interior and exterior wall decoration.

Aluminum sheet for aluminum alloy shutters

Aluminum is a Common Material for Aluminum Alloy Shutters With the continuous development and progress of science and technology, the aluminum products industry is growing rapidly, especially in the production of aluminum alloy shutters. Aluminum alloy shutters are a widely used window that is more common in daily life. Its material is made of aluminum alloy that is not easy to rust. It is not only strong in material, but also has a long service life, which is favored by the market.

Advantages of 3004 aluminum alloy shutters

1. Light weight, easy to use, high bending strength, not easy to deform during processing;

2. It has the characteristics of good water resistance, elasticity and durability, and has good shading properties;

3. Corrosion resistance, 3004 aluminum alloy is not easy to rust and easy to clean;

4. The aluminum alloy surface is smooth and bright, and the aluminum alloy shutters are beautiful in shape.

3004 aluminum alloy information

3004 aluminum alloy is a commonly used grade of aluminum-manganese alloy. Its strength is not high, but it is higher than 3003 aluminum plate and pure aluminum plate. It has good formability and high corrosion resistance. It is usually used to improve its mechanical properties. 3004 aluminum strips are mainly used in chemical product production and storage devices, thin plate processing parts, wide curtain wall panels, liquid crystal back panels, various lamps, lamp holders, beverage cans, colored aluminum plates, etc.

Aluminum plate for doors

Aluminum plates are commonly used in doors

Aluminum plates are frequently used as the main material for door panels. They provide a durable and rigid surface that forms the visible face of the door. Aluminum panels can be flat or have raised or recessed patterns for aesthetic purposes.

Aluminum plates are utilized for constructing frame components of doors. This includes door jambs, stiles, and rails. These frame components provide structural support and help secure the door panels in place.

Performance advantages of aluminum plates for door panels

Lightweight and Corrosion Resistance

Aluminum panels are lightweight compared to other materials such as steel or wood. This lightweight nature makes them easier to handle, install, and operate, resulting in improved usability and reduced strain on hinges and hardware.

Aluminum panels have inherent corrosion resistance. They are not susceptible to rust or corrosion, making them ideal for doors exposed to moisture, humidity, or harsh environments. This resistance to corrosion ensures the door’s longevity and reduces the need for frequent maintenance or replacement.

Color coated aluminum roof

After cleaning, chromizing, roller coating, baking and other processing, the surface of the aluminum coil is coated with various colors of paint. This kind of aluminum coil is called color coated aluminum coil. Colored aluminum is widely used in roofs due to its advantages of light texture, bright color, easy processing and forming, and no rust.

Conventional alloys are 1100, 1050, 1060, 1070, 3003, 3004, 3105, 5052, 5005, etc.

The thickness is 0.2mm-6mm, and the coating thickness is 5-25UM.

The surface color is rich, which can be painted with imitation stone grain color, imitation wood grain color aluminum plate, printed color aluminum, brushed color aluminum, etc.

According to different use requirements, it can be divided into PE color coated aluminum plate and PVDF color coated aluminum plate, which can guarantee color fastness for 10-20 years.