Product introduction

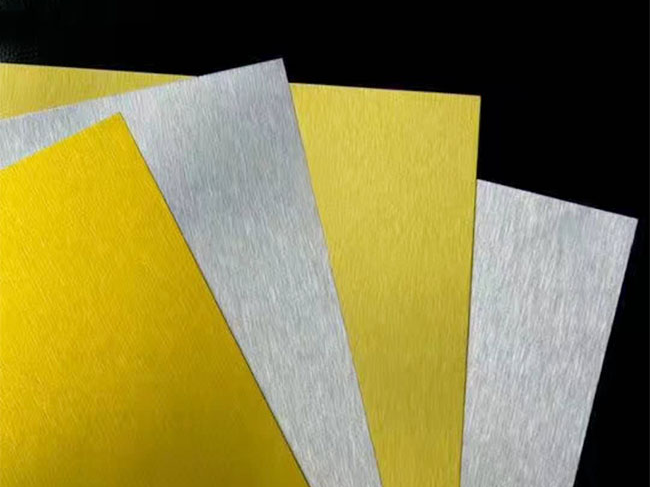

Color-coated aluminum sheet, also called color-coated aluminum coil, color-coated aluminum plate, color-coated aluminum coil, aluminum-magnesium-manganese color-coated plate, etc., is a new environmentally friendly product coated with an organic coating on an aluminum plate and cured at high temperature.

Color-coated aluminum refers to the coloring of the surface coating of aluminum panels. Common fluorocarbon color-coated aluminum and polyester color-coated aluminum are widely used in aluminum-plastic panels, aluminum veneers, aluminum honeycomb panels, aluminum ceilings, and roof surfaces. Leftovers, cans, electronic products. Its performance is very stable and not easy to be corroded. The surface layer can be guaranteed for 30 years after special treatment. The weight per unit volume is the lightest among metal materials. Color-coated aluminum plate is currently the most popular new type of aluminum material.

Specification

| Name | Color Coated Aluminum sheet/plate |

| Alloy | 1100 3003 3004 3105 5052 8011 |

| Temper | H16. H18. H24. H26. H28 |

| Coating paint | AC,PE,HDPE,Epoxy,PVDF,FEVE ect |

| Coating thickness | PE:>=18 micron , PVDF:>=25 micron |

| Coated Color | Single ,wooden,stone,gloss,mirror,RAL As customer requirements. |

| Thickness | 0.02mm-5.0mm |

| Width | 500-1520m |

| Protective film | As customer requirement , can print customer logo |

| Coating Hardness (pencil resistance) |

More than 2h |

| Coating Adhesion | 5J(EN ISO-2409:1994) |

| Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

| Flexibility (T-bend) | ≤2T |

| MEK Resistance | More than 100 |

Chemical Composition (For Reference)

Chemical Composition conforms to Chinese, American and European standard specification

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each |

Others: Total |

Al:Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

| 1050A | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.07 | 0.05 | 0.03 | - | 99.50 |

| 1100 | 0.95 Si + Fe | 0.05~0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.15 | 99.0 | |

| 3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | remainder |

| 3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | remainder |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | remainder |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | - | 0.05 | 0.15 | remainder |

Alloy and Temper

| Alloy | Temper | Remarks |

| 1xxx: 1050, 1050A, 1100 | H42, H44, H46, H48 | ★Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. |

| 3xxx: 3003, 3105 | ||

| 5xxx: 5005, 5052 |

Alloy Designation (For Reference)

Comparison of Alloy Designations

| Alloy | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | - | - |

| 1050A | - | EN AW-1050A | |

| 1100 | 1100 | - | |

| 3xxx Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Temper Designation (For Reference)

| Temper | Definition |

| H42 H44 H46 H48 |

Strain Hardened and painted or lacquered, 1/4 Hard Strain Hardened and painted or lacquered, 1/2 Hard Strain Hardened and painted or lacquered, 3/4 Hard Strain Hardened and painted or lacquered, Full Hard |

| Temper H12, H14, H16, H18, H22, H24, H32 and H34, for base material are provided as per client’s request and mutually agreed. | |

Available Size Range:

| Dimension | Range |

| Thickness | 0.25 ~ 1.8 mm |

| Diameter | 500 ~ 1,550 mm |

| Length | Coiled, or 2,000 ~ 4,000 mm |

*Cut to length service is available for thickness over 0.5mm

Coating

| Paint | PE (Polyester), PVDF |

| Coating Thickness | Front side: ≥ 18 microns(PE), ≥25 microns(PVDF) Back side: 8~10 microns (PE or EP) |

| Coating Color | RAL colors, or by confirmed sample (customized) |

- Surface Protection: With PE/PVC film on main side (if specified)

- Gloss: 20% to 80%, depends on client’s requirement.

- Coil ID: 405mm, 505mm, 605mm

- Minimum Order Quantity: 5MT per size, total 20MT for one order

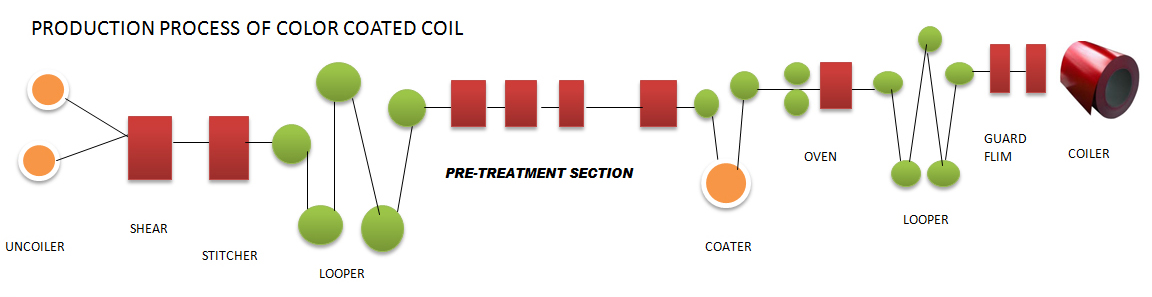

Roll Coating Process

Application

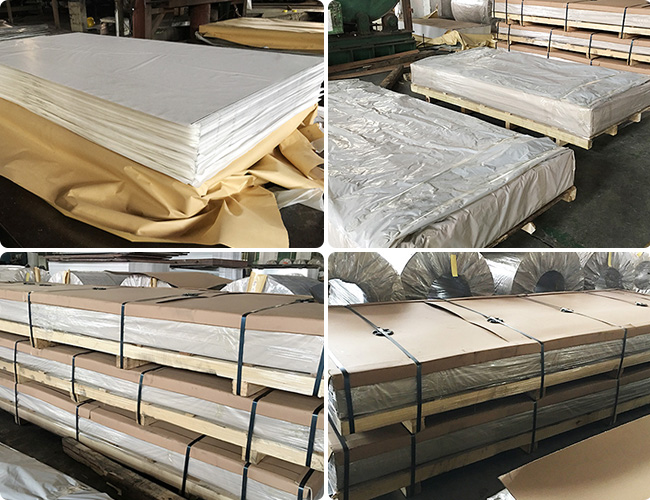

Packing

Packing Details : Standard export package.

Aluminium Sheet of packaging meet the export standard. Plastic film and brown paper can be covered at customers’ need. wooden case or wooden pallet is adopted to protect products from damage during the delivery.

FAQ

What are the common substrate materials for color-coated aluminum plate?

Aluminum and aluminum alloy groups are divided into 8 categories, and the commonly used aluminum plate materials for color-coated aluminum plates are mainly 1 series, 3 series, and 5 series. The material characteristics and differences of each series of aluminum plates are as follows:

Series 1 is pure aluminum. Since it does not contain other alloying elements, the production process is relatively simple and the price is relatively cheap. It is one of the more commonly used materials in color-coated aluminum plates. However, because it is pure aluminum, the material is relatively soft. Commonly used materials are 1060 series.

Series 3 is an aluminum-manganese alloy. The alloy component is mainly manganese. The content is between 1.0-1.5. It has good anti-corrosion properties. We also call it anti-rust aluminum. The material hardness is higher than that of pure aluminum in Series 1, and its tensile properties are also better. Better than 1 series, it is one of the most commonly used materials in color-coated aluminum panels. Commonly used materials are 3003 series and 3004 series, but the price is higher than 1060 series. In addition, in addition to manganese, the 3004 series also adds magnesium, with a content between 0.8-1.3%. We usually also call the 3004 series aluminum magnesium manganese, and its strength is higher than that of the 3003 series.

Series 5 is an aluminum-magnesium alloy. The alloy composition is mainly magnesium, and the magnesium content is between 3 and 5. Its main features are low density, high tensile strength and high elongation. Due to its low density and light weight, 5 series aluminum-magnesium alloys are often used in the aviation field and are called aviation aluminum. They are sometimes used to produce color-coated aluminum sheets. In terms of mechanical properties, the 5 series aluminum plate has higher tensile strength than the 3 series aluminum plate, and its performance is also better than the 3 series aluminum plate. Of course, the price is relatively high, and the commonly used material is the 5052 series.

What types of color-coated aluminum plate are there?

1.Based on the base material material, it can be divided into: 1100 color aluminum plate, 1060 color aluminum plate, 3003 color aluminum plate, 3004 color aluminum plate and other categories. Colored aluminum plates of different materials have different hardness and strength;

2.Based on the paint thickness, it can be divided into: single-coated colored aluminum plate and double-coated colored aluminum plate;

3.Based on the paint material, it can be divided into three types: polyester paint colored aluminum plate, fluorocarbon paint colored aluminum plate, and epoxy paint colored aluminum plate.