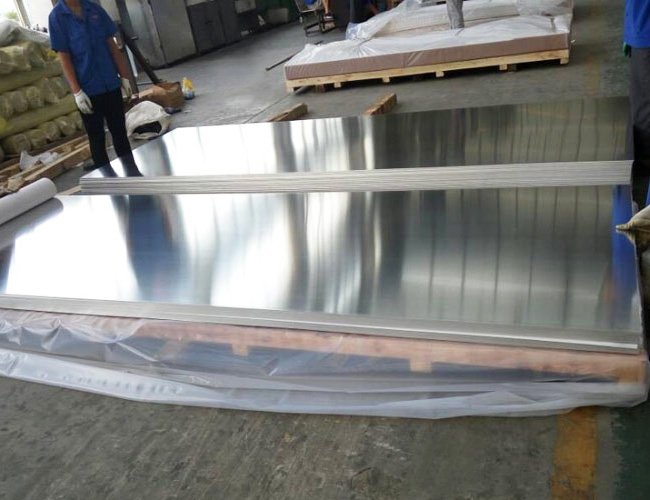

Product introduction

Aluminium Plain Sheet is a lightweight, corrosion-resistant material commonly used in the automotive industry for various purposes. It usually comprises 99% aluminium alloy and 1% or fewer elements such as iron, silicon, magnesium and copper. Aluminium Plain Sheet often presents superior characteristics like a high strength-to-weight ratio, excellent formability and weldability. These qualities make it ideal for use in automobiles due to its low weight yet strong protective properties. It has diverse applications in many other industries.

Technical Parameter

| Aluminium Alloy | Thickness (mm) |

Width (mm) | Length (mm) | Temper | |

| A1050,A1060,A1070,A1100 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 | |

| A3003,A3004,A3105 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 | |

| A5052,A5005,A5083,A5754 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H34,H32,H36,H111,H112 | |

| A6061,A6082,A6063 | 0.15-200 | 20-2620 | 20-8000 | T4,T6,T651 | |

| A8011 | 0.15-200 | 20-2620 | 20-8000 | O,H12,H14,H16,H18,H22,H24,H26 | |

| Standard Width | 1000mmx2000mm,1220x2440mm,1250x2500mm,1500x3000mm | ||||

| Material process | CC AND DC | ||||

| Customerize size | Size can be produced as per clients requirement | ||||

| Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing | ||||

| Mirror,Brush,Perforated,Tread plate ,Corrugated etc | |||||

| Quality Standard | ASTM B209,EN573-1 | ||||

| MOQ per size | 2 tons | ||||

| Payment Terms | TT OR LC OR DP at sight | ||||

| Delivery time | Within 25 days after receipt the lc or deposit | ||||

| Material Quality | Tension levelled ,flat ,Free of defects like oil stain,Roll Marks,Waves,Dents | ||||

| scratches etc ,A+++ quality, production process passed sgs and bv inspection | |||||

| Application | Construction ,Building,Decoration ,Curtain Wall ,Roofing,Mould,Lighting, | ||||

| ship building,Aircraft,Oil Tank ,Truck Body etc | |||||

| Packing | Standard export worthy wooden pallets,and standard packing is about 2 tons/pallet | ||||

| Pallet weight also can be as per client's requirement | |||||

Advantages of Using Aluminium Plain Sheet

Strength and Durability

They have many advantages over other materials. It is strong, lightweight, and durable. Its strength-to-weight ratio is higher than steel, meaning it’s a great choice for high-load applications like bridges and boats. Furthermore, plain aluminium sheets are corrosion-resistant, ideal for coastal marine construction projects or areas with high humidity. Additionally, they can be formed into various shapes to provide flexibility in design options when fabricating components or structures. Ultimately, plain aluminium sheets offer an excellent combination of strength and durability at a fraction of the cost compared to other metals.

Lightweight and Cost-Effective

The plain aluminium sheet is incredibly lightweight, which makes it an ideal material for construction projects. Lightweight materials make it easier to transport, manipulate and work with on-site. Furthermore, using plain aluminium sheets in construction is cost-effective, as it reduces transportation, labour, and material costs. This makes it an affordable alternative to traditional construction materials.

Versatile Applications

They offer a versatile range of applications due to their excellent properties. It is highly corrosion-resistant, lightweight yet strong enough and has good heat conductivity. Also, it provides low-cost production with various shapes and thicknesses available for customizing. Moreover, this material is 100% recyclable, making it an environmentally friendly option for construction and manufacturing projects.

Easy to Maintain

Aluminum plain sheet has many advantages, making it a great choice for many applications. It is lightweight but still strong and durable, which makes it very easy to install and maintain. Furthermore, aluminium sheets are resistant to rust and corrosion, ensuring that whatever you build with them will last for years without worrying about deterioration. Additionally, aluminium is 100% recyclable – meaning that when you need new sheets or want to replace any parts of your project with newer materials, you can easily recycle the old pieces without hurting the environment.

Environmentally Friendly

The plain aluminium sheet is eco-friendly, as it is 100% recyclable. Recycling aluminium requires only a fraction of the energy required to produce new aluminium. This makes plain aluminium sheets a perfect choice for construction companies looking to reduce their carbon footprint and promote sustainability. Using aluminium in construction reduces the demand for other non-renewable resources.

Plain aluminium sheet with factory applied

Plain aluminium sheet has been one of the most raw material for many industries with factory applied. Here are the main introduction of the plain aluminum sheet from 1000 series to 7000 series.

1000 series: Aluminum content more than 99.00%, good electrical conductivity, corrosion resistance and welding performance, low strength, no heat treatment strengthening. Application range are mainly used in science testing, chemical industry and special applications.

2000 series: Aluminum alloy containing copper as the main element. Manganese, magnesium, lead and antimony are also added for machinability. Applications are aviation industry (2014 alloy), screws (2011 alloy) and industries with higher temperature (2017 alloy).

3000 series: Aluminum alloy with manganese as the main alloying element, can not be heat-treated and strengthened, 3000 series aluminium plain sheet has good corrosion resistance, welding performance and plasticity. Disadvantages are low strength, but can be strengthened by cold work hardening. Applications are oil-conducting seamless pipes used on aircraft(3003 alloy) and cans (3004 alloy).

4000 series: mainly based on silicon, not commonly used. A part of 4000 series aluminum is heat treatable.

5000 series: Aluminum alloy mainly based on magnesium. 5000 series aluminium sheet has good resistance, welding performance and fatigue strength, no heat treatment and strengthening, only cold processing to improve strength. Applications are marine boats, yachts, lawn mower handles, aircraft fuel tank conduits and body armor.

6000 series: Aluminum alloy mainly based on magnesium and silicon. 6000 series sheet aluminium has medium strength, good corrosion resistance, welding performance, process performance and oxidation coloring performance. Applications are car luggage racks, doors, windows, body, heat sinks, compartments.

7000 series: Aluminum alloy mainly based on zinc, a small amount of magnesium, copper, good welding performance. 7005 and 7075 plain aluminium sheet are the highest grades in the 7000 series and can be heat treated and strengthened. Applications are aircraft load-bearing components, landing gear, rockets, propellers, aviation spacecraft.