Product introduction

Alloy 5083 aluminum plate sheet have higher strength than 5052 aluminum plate and has exceptional thermal conductivity. In the tempered condition, it retains good formability due to excellent ductility. It is highly suitable for welding and can be hardened by cold work. Because Alloy 5083 exhibits excellent resistance to general corrosion, it is used in marine applications. Since Alloy 5083 is capable of withstanding extremely low temperatures without brittleness or loss of properties, it is especially suited to the cryogenic market.

What is Aluminium 5083 Sheet & Plate?

The ALUMINIUM 5083 Plates are made from the aluminium alloy having magnesium and chromium with it. These steel plates are having many of the greater features which have provided usable results. These plates are having much of the Resistance to seawater and industrial chemicals. They are also resistant to all other types of corrosive materials and hostile environment. The alloy is also compatible with the welding process even at the lower temperature and does not require any type to pre or post heating.

This alloy is having much greater strength and it can retain its exceptional strength even after welding. It also becomes hardenable after welding at the cold working. Even though it has welding done at cold working, it is also having higher heat resistance and thus it can be used at the higher temperature too. This alloy is having exceptional thermal conductivity. In the tempered condition, it can have good formability as it is having excellent ductility. Therefore due to this property, it can be formed in different shapes and sizes of all the standards and also in the custom size. This alloy is having the capacity to Withstand in any temperature from high to low and its properties will not be affected and so its plates are.

Aluminium 5083 is known for exceptional performance in extreme environments. 5083 is highly resistant to attack by both seawater and industrial chemical environments. Alloy 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65°C.

Technical Parameter

|

Alloy |

5083 |

|

Temper |

F,O,H12,H14,H16 H18,H19,H22,H24,H26,H28,H111,H112,H114 |

|

Thickness(mm) |

0.5-500 |

|

Width(mm) |

100-2650 |

|

Length(mm) |

500-16000 |

Chemical Composition

| ELEMENTS | Mg | Si | Iron | Ti | Cu | Mn | Cr | Zn | Others Total | Alu |

| CONTENT (WT%) | 4.0-4.9 | ≤0.4 | 0.4 | ≤0.15 | ≤0.1 | 0.4-1.0 | 0.05-0.25 | 0.25 | 0.15 | Remain |

Mechanical Properties and Tempers

| Typical Temper | Tensile Strength(KSI) | Yield Strength(KSI) | Elongation(%) | Thickness(mm) | Width(mm) | Length(mm) |

| O(annealed) | 42 | 21 | 14 | 0.2-350 | 500-3100 | Max1600 |

| H122 | 43 | 23 | 10 | |||

| H116 | 46 | 33 | 10 | |||

| H321 | 48 | 33 | 10 |

Product character:

1. Superior corrosion resistance,

2. Good weldability,

3. High fatigue resistance.

4. Possess high strength,

5. Good processability

6. Excellent corrosion resistance.

7. Large specification.

Classification

|

product |

5083 aluminum plate sheet |

|

Aluminum plate variety |

Ordinary aluminum plate, bright aluminum plate, wire drawing aluminum plate, film coated aluminum plate, super flat aluminum plate, imported aluminum plate and patterned aluminum plate |

|

standard |

GB、ASTM、EN |

|

Delivery status |

o、H111、H112、H116、H131、H32、H321 and so on |

|

thickness |

0.5-450mm |

O: The annealed condition is applicable to the processed products (occasionally) that have been fully annealed to obtain the lowest strength

H: Non heat treatment strengthened aluminum alloy

The first digit indicates the method of work hardening.

The second digit indicates the degree of hardening achieved by the material.

H followed by an Arabic numeral

H1 only indicates the work hardening state, which is applicable to the products that obtain the specified strength without heat treatment after work hardening;

H3 work hardening and stabilization state is applicable to products with stable mechanical properties after work hardening through low-temperature heat treatment or due to the thermal effect during hot working. Stabilization can usually improve ductility. This code is only applicable to alloys that gradually age soften at room temperature.

HX1 (x for 1, 2, 3) followed by an Arabic numeral

H1, H2 and H3 status codes are followed by an Arabic numeral to indicate the degree of work hardening

Hxx code followed by Arabic numerals

When there is a difference but close to the control degree or mechanical properties (or both) of hxx state, or there is a significant impact on the determination of other characteristics, the third Arabic numeral shall be used.

For example, Hx11 is suitable for sufficient work hardening when the final annealing does not meet the requirements of annealing state,

However, the work hardening degree is not completely consistent with the HX1 state;

H112 is applicable to products with certain characteristics obtained during thermal processing, which have mechanical property requirements.

5083 H111 VS H112 VS H116

Aluminum sheet 5083 H116 For products made of 5xxx series alloys with a magnesium content of 4% or more. These products have the required mechanical properties and resistance to spalling and corrosion.

Aluminum sheet 5083 H111, full annealed products that have undergone a moderate amount of work-hardening, but can’t reach the hardness of the H11 condition.

Aluminum sheet 5083-H112: Applicable to products that are hot rolled. The mechanical properties of products in this condition are required by regulations.

Aluminum sheet 5083-H321: This is suitable for processing aluminum materials with magnesium content greater than 4%, and the degree of work hardening in both hot and cold working is slightly less than that of H32. The technical parameters of H116 are demanding, with strict requirements for anti-corrosion properties and magnesium content; however, H321 has good performance stability.

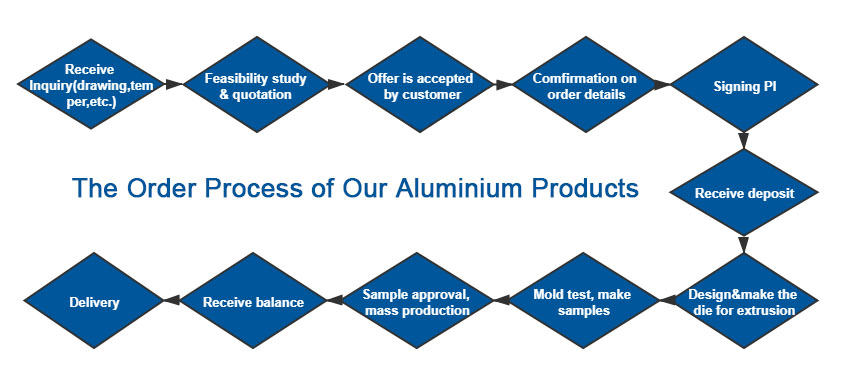

Order Process

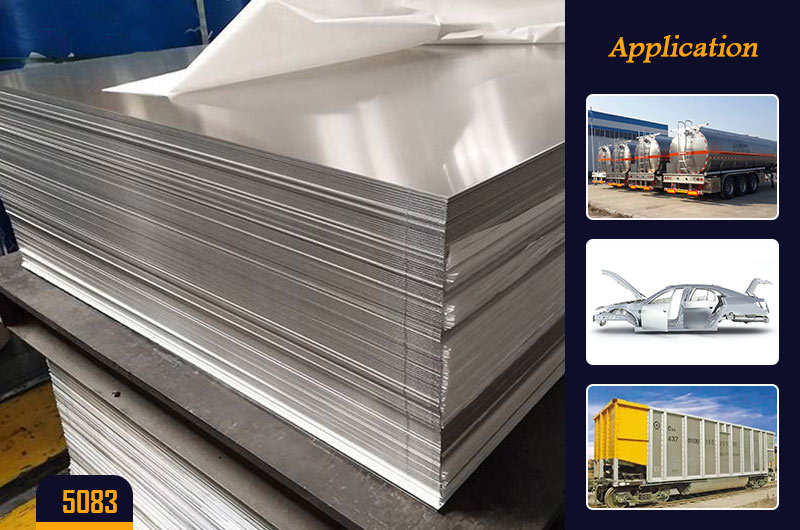

Other applications of 5083 alloy:

5083 aluminum alloy can not only be used as plate in shipping and transportation industries, but also as aluminum foil, aluminum strip and aluminum profile in all aspects of life. For example:

1. 5083 pattern aluminum plateis used for anti-skid of refrigerated vehicles, cold storages, refrigerators and subways

2. 5083 aluminum coil is used for auto parts, high voltage switch, ship plate, tank car, etc

3. 5083 aluminum plate for tank body of tank car is used for tank car, automobile, bus, ship, etc

4. 5083 die aluminum plate is used for die, ship plate, automobile and electronic products

5. 5083 aluminum sign blank

Packaging