Product introduction

3A21 aluminum plate is al-mn alloy, 3A21 aluminum plate is a widely used rust-proof aluminum, the strength is not high, can not heat treatment strengthening, so often use cold processing method to improve its mechanical properties;High plasticity in annealing state, good plasticity in semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, good weldability, poor machinability.

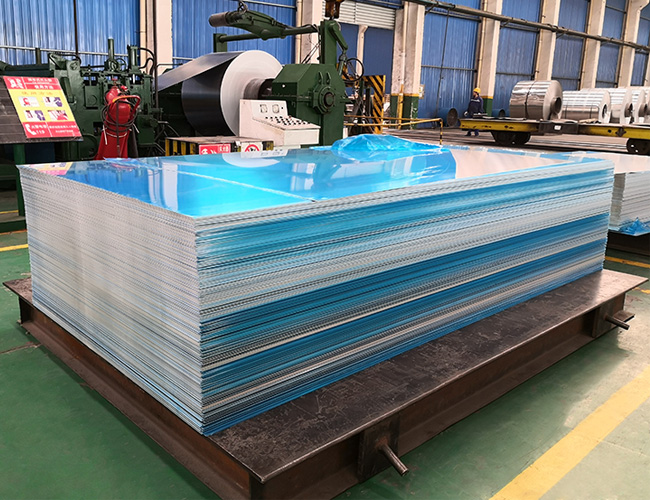

We can produce 3A21 hot rolled aluminum sheet with maximum width of 2650mm and maximum thickness of 4.5mm.

Technical Parameter

Typical Alloy |

3A21 Aluminum plate |

|

Material Temper |

O,H12,H14,H16 |

|

Thickness(mm) |

0.2-300 |

|

Width(mm) |

100-2650 |

|

Length(mm) |

500-16000 |

|

Typical Products |

Body cover, roof, floor, etc |

Characteristics of 3A21 aluminum alloy

3A21 aluminum plate is al-mn alloy, 3A21 aluminum plate is the most widely used rust-proof aluminum, the strength is not high (only slightly higher than industrial pure aluminum), can not heat treatment strengthening, so often use cold processing method to improve its mechanical properties;High plasticity in annealing state, good plasticity in semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, good weldability, poor machinability.

Range of application

Applications are mainly used for low load parts which require high plasticity and good weldability and work in liquid or gas medium, such as oil tank, gasoline or lubricating oil conduit, various liquid containers and other small load parts made of deep pull: wire for rivet.Aluminum plate 3003 has good formability, solubility and corrosion resistance.Used for processing and need to have good formability, high corrosion resistance of the weldability of good parts, components, or both require these performance and needs to have more than 1 XXX alloy high strength work, such as kitchen utensils and appliances, food and chemical products processing and storage devices, and transportation of liquid product tank, tank, with sheet processing all kinds of pressure vessel and pipeline generally implements, radiator, makeup, copy machine roller, ship material.

Chemical composition

Aluminum Al: margin

Si Si: 0.6 or less

Copper Cu: 0.20 or less

Magnesium Mg: 0.05 or less

Zinc and zinc: 0.10 or less

Mn: 1.0 ~ 1.6

Ti Ti: 0.15 or less

Ti+Zr: limit T I +Zr ≤0.20 for extrusion and forging products

Iron Fe: 0.000 ~ 0.700

Note: single :≤0.05;Total: 0.10 or less

Heat treatment specification

1) homogenization annealing: heating 510 ~ 520℃;Heat preservation 4 ~ 6h;Air cooling.

2) rapid annealing: heating 350 ~ 410℃;With different effective thickness of the material, the holding time was 30 ~ 120min.Air or water is cold.

3) high temperature annealing: heating 350 ~ 500℃;When the thickness of the finished product is ≥6mm, the holding time is 10 ~ 30min, and when the thickness is less than 6mm, the heat transmission will stop.Air cooling.

4) low-temperature annealing: heating 250 ~ 300℃;The holding time is 1 ~ 3h;Air or water is cold.

State: aluminum and aluminum alloy pressed plate (0.6 ~ 0.8mm,HX8 state).

Packing Detail

The standard export packaging, plastic film or craft paper covered at customers’ requirements. Wooden case or wooden pallet is adopted to protect products from damage during the delivery.