1060 aluminum sheet plate belongs to 1000 series aluminum sheet, which is pretty similar to 1050 aluminum alloy with more than 0.1% of aluminum by weight.

Both 1050 and 1060 aluminum sheet of Haomei aluminium, lives up to ISO standards, but they cover different ASTM standards. 1060 aluminum alloy contains 0.05% cooper, thus, its conductivity is 55%.

Besides, 1060 aluminum sheet is relatively low strength, essentially pure aluminum alloy with many different tempers, such as O (annealed), H12, H14, H16, H18, etc. what’s more, other aluminum sheets belonging to the commercially pure wrought family are available, including 1050, 1070, 1100 and so on and so forth.

Product introduction

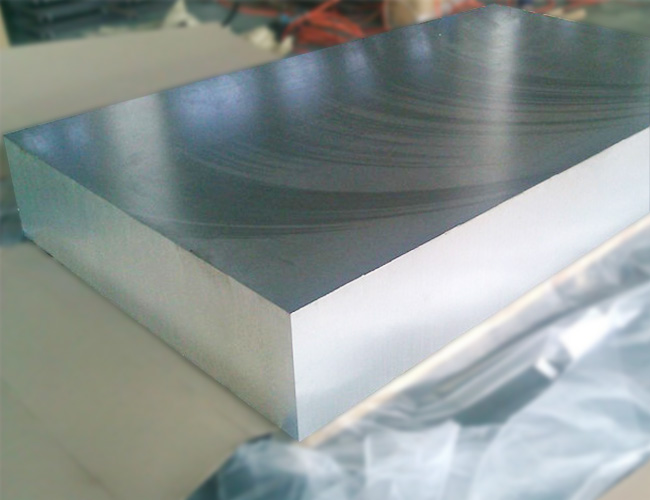

We have been focusing on the r&d and production of hot rolled 1060 aluminum plate for 30 years. 1060 aluminum plate has the advantages of high elongation, high tensile strength, excellent electrical conductivity and high formability, which can fully meet the requirements of conventional processing (stamping, stretching).We are one of the few manufacturers in China that can produce ultra-wide and ultra-thick aluminum plates. The ultra-wide and ultra-thick 1060 aluminum plates are produced with the widest width of 2650mm and the thickest thickness of 500mm. The internal stress is eliminated and the cutting does not deform.

Technical Parameter

Typical Alloy |

1060 Aluminum plate |

|

Material Temper |

O,H12,H14,H16 |

|

Thickness(mm) |

0.1-500 |

|

Width(mm) |

100-2650 |

|

Length(mm) |

500-16000 |

|

Typical Products |

Bus bar, power battery soft connection, aluminum-plastic board, lamp material, etc |

Feature

1060 aluminum sheet Has good elongation and tensile strength, can satisfy completely the requirements of conventional processing (stamping, stretch) high formability.

For industrial pure aluminum, high plasticity, corrosion resistance, electrical conductivity, and thermal conductivity, but strength is low, heat treatment can not be improved machinability is bad; Gas welding, hydrogen welding, and resistance welding are not easy to brazing; Under various pressure processing and extension, bending.

Scope of application

Aluminum plate belongs to industrial pure aluminum, with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not be strengthened, machinability is not good;Gas welding, hydrogen welding and contact welding, not easy brazing;Easy to bear all kinds of pressure processing and extension, bending.

1060 aluminum plate is widely used in the strength requirements of the product.Products are often used in signs, billboards, building exterior decoration, bus body, tall buildings and factory wall body adornment, kitchen sink, lamp holder, fan blade, electronic parts, chemical equipment, mechanical parts, deep drawing of sheet or spinning concave ware, welding part, heat exchanger, clock surface and plate, plate, kitchenware, ornaments, reflective equipment, etc.

Ingredients

Silicon aluminum Al (99.60%), Si (0.25%), copper Cu (0.05%), magnesium Mg (0.03%), zinc zinc (0.05%), manganese Mn (0.03%), titanium Ti (0.03%), V V (0.05%), iron Fe (0.350%).

Mechanical properties

Tensile strength b (MPa) Elongation = 10 (%)

110-136- 3-5

Chemical composition

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | |||

| Content (max) | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.15 | Remain | |||

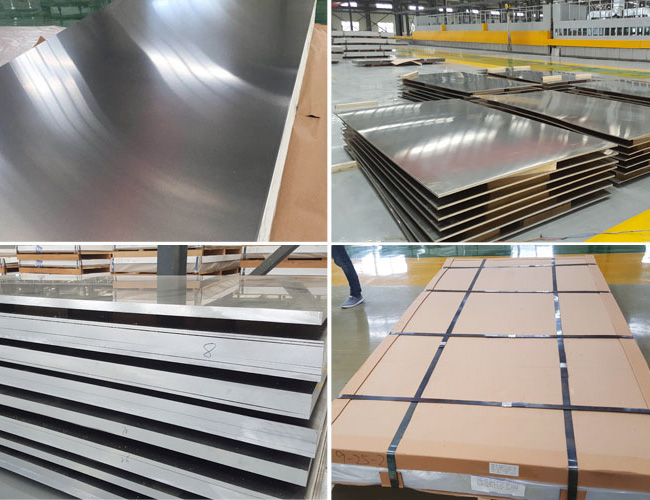

Packing

1060 Aluminum Sheet of the packaging meets the export standard. Plastic film and brown paper can be covered at customers’ needs. A wooden case or wooden pallet is adopted to protect products from damage during delivery.