Product introduction

Alu alu foil also called medical aluminum foil.

Medical packaging must meet the requirements of moisture-proof, mildew proof, antifreeze, heat proof, light proof, etc. Aluminum is nontoxic and tasteless. It has excellent blackout, dampproof, gas resistance and odor retention.

Theoretically, perfect aluminum foil can completely block any gas and light, and can protect the package most effectively. Almost all materials that require no light transmission and high barrier are made of aluminum foil as barrier layer. Therefore, aluminum foil has been widely used in pharmaceutical packaging industry, and is often used as barrier layer Use of inner packaging materials in direct contact with drugs

Blister packaging is to place the medicine in blister or blister eye of the plastic hard film formed by Blister molding, and then glue the plastic hard film with the aluminum foil printed and coated with protective agent and adhesive by heat sealing.

In addition to the necessary advantages of light shielding and barrier, blister packaging has been widely used in pharmaceutical packaging due to its unique punctuality. Moreover, aluminum foil for blister packaging can complete the printing, protective agent coating, adhesive coating process and corresponding drying process on one device at a time, which is suitable for mass production.

Therefore, aluminum foil for blister packaging is also the main application of aluminum foil in the field of pharmaceutical packaging.

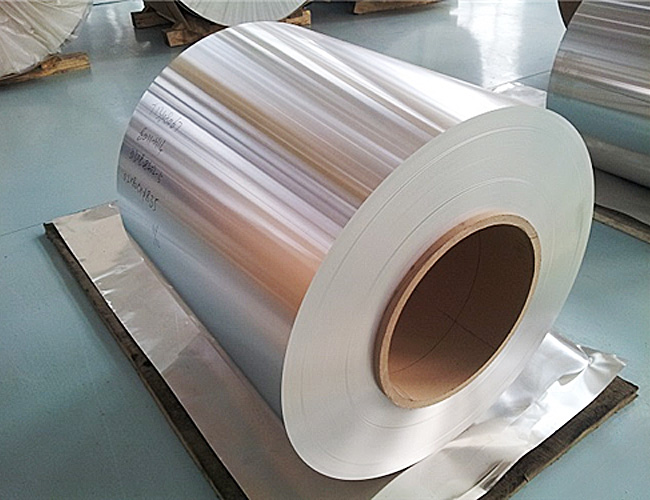

Specifications

| Al metal alloy | 1000, 3000, 8000 series |

| Alu temper | O - H112 etc |

| Width | < 700mm |

| Thickness | 140 - 160μm |

| Core ID | 76mm |

| OD ( outer diameter ) | 240mm - 280mm |