Product introduction

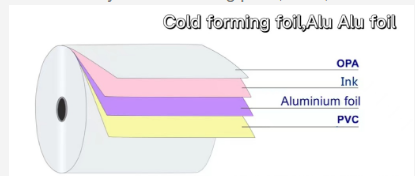

COLD FORMING BLISTER FOIL is one product dedicated to pharmaceutical industry manufactured by sandwiching aluminum foil between nylon (oPA) and PVC films using dry bond lamination technology. As blisters are formed in this Nylon / Foil / PVC film laminate by pressing laminate into a mould by a stamp without applying heat, the material is called cold forming blister laminate. The laminate offers a near complete barrier for water and oxygen thereby allowing an extended product expiry date due to higher thickness of the foil present in the laminate. The PVC film in alu-alu laminate is commonly used as the contact layer and seal to layer on pharmaceutical blister (as neutral layer for the goods to be filled). PVC is very stiff and does not tend to shrink or spring during cold forming. Once the cold forming process is complete, the PVC helps the cavity hold its shape. In short it ensures the geometric stability after cold forming. The nylon (oPA) film is mainly responsible for the multi-axial forming. Laminating the aluminum with the oPA film doubles the formability of the foil.

The covering material of cold-formed blister packaging is usually aluminum foil, and the base material for forming the blister is usually a rigid polyvinyl chloride sheet. Due to the limited barrier properties of the latter, it is difficult to ensure the quality of the drug within the period of use. Therefore, now people have developed a cold stamped hard sheet, which uses stamping to replace the original ordinary blister packaging.

The application of high-strength cold forming blister foil in the cold stamping hard sheet makes the cold stamping hard sheet have extremely high resistance to water vapor and oxygen and light insulation, which is unmatched by any other material.

Cold Form Aluminum Foil, also named cold formed foil, is a easy shaping blister packing material for medication. With the aluminum surface, it provide better barrier effect for the drugs inside from steam and oxygen.

Specification

|

Alloy-temper |

8011/1235/ 8079-O H18 |

|

Thickness |

0.02mm(20micron) - 0.03mm (30micron) (tolerance:±5%) |

|

Width and tolerance |

200- 1500 mm (tolerance:± 1.0mm) |

|

Weight |

100 - 250kg per roll coil (or customized) |

|

Surface |

one side matte, one side bright |

|

Packaging |

Fumigation free wooden cases(keep us informed if any special requests) |

|

Application |

used in pharmaceutical packing,medical packaging ,Medicine pack et |

|

Application |

Alloy |

Temper |

Thickness(mm) |

Width(mm) |

Typical uses |

|

PTP foil |

8011 |

O/H18 |

0.016-0.5 |

100-1700 |

Capsule cover plate |

|

Blister foil |

8021 |

O |

0.04-0.065 |

100-1700 |

Blister packaging |

|

Tropical medicinal aluminum foil |

8021/8079 |

O |

0.016-0.2 |

100-1700 |

High-end pharmaceutical packaging |

|

Aluminum foil for medicine caps |

8011 |

H14/H16 |

0.016-0.5 |

100-1700 |

Oral liquid aluminum-plastic composite cap, infusion bottle aluminum-plastic cap, etc. |

Characters

* Full barrier against water vapor, oxygen,gases, light;

* Excellent Thermo-formability

* High degree of Thermal stability

* High Malleability for deep drawing blister cavities

* Sealable with normal aluminum Foil

* Effective anti-counterfeit packaging

* Extended product expiry date