Product introduction

Coated aluminum foil is a specially treated material made of coated aluminum foil substrate, which has properties such as moisture-proof, anti-corrosion, and radiation protection. Its main components are aluminum foil and coating materials. The coating materials usually include plastic materials such as polyethylene, polypropylene, and polyvinyl chloride.

1. Aluminum (Al): Aluminum is the main component element of coated aluminium foil, accounting for most of the content. Aluminum has good thermal and electrical conductivity, is lightweight and easy to process, so it is widely used in fields such as food packaging, building materials and industrial materials.

2. Polyethylene (PE): Polyethylene is a common coating material with good moisture-proof and anti-corrosion properties. It can effectively protect the aluminum foil substrate and reduce environmental pollution. Polyethylene also improves the processability and plasticity of coated aluminum foil.

3. Polypropylene (PP): Polypropylene is also a commonly used coating material with excellent wear resistance and chemical resistance, which can effectively enhance the mechanical strength and durability of coated aluminum foil.

4. Polyvinyl chloride (PVC): PVC is a plastic material with good moisture-proof and heat-insulating properties. It can effectively reduce the thermal conductivity of coated aluminum foil and has good properties for susceptible products such as food and pharmaceuticals. protective effect.

5. Other additives: Coated aluminum foil may also add some other materials, such as antioxidants, plasticizers, fire retardants, etc., to improve the performance and durability of coated aluminium foil.

In general, the components of coated aluminum foil mainly include aluminum and one or more coating materials. These materials interact to form a new material with excellent properties and are widely used in packaging, construction, electronics, medicine and other fields.

Specifications

| Alloy | 1060, 1100, 1235, 3003, 8011, 8021, 8079, etc. |

| Temper | O、H18、H22、H24 |

| Thickness | 0.006-0.2 mm |

| Widthness | 100-1600 mm |

| Length | C |

| Typical Products | Food packaging, pharmaceutical packaging, insulation materials, industrial materials, etc. |

PROCESSING TECHNOLOGY

Coated aluminum foil is a process in which other materials are coated on the surface of aluminum foil to change its properties and uses. The coated aluminum foil processing technology mainly includes material preparation, surface treatment, coating, drying and coiling.

First, prepare materials. Choose high-quality aluminum foil as the base material, and determine the materials that need to be coated according to different usage requirements, which usually include polymer resins, coating agents and other additives.

Secondly, carry out surface treatment. The surface of the aluminum foil needs to be degreased, deoxidized and roughened to ensure that the coating can adhere firmly to the surface of the aluminum foil and provide better coverage and adhesion.

Next, proceed to the coating operation. The pre-prepared coating material is usually evenly coated on the surface of the aluminum foil using roller coating, blade coating or spray coating to form the required functional coating. During the coating process, parameters such as coating speed, coating thickness, temperature and humidity need to be controlled to ensure the quality and uniformity of the coating.

Then, drying is performed. After the coating is completed, it needs to be dried to remove the solvent in the coating and ensure that the coating can be fully cured and firmly bonded to the aluminum foil surface. Usually an oven or drying chamber is used for heat treatment, and ultraviolet curing technology can also be used for rapid curing.

Finally, take up the coil. The dried coated foil is rolled into rolls or cut into sheets. After packaging and quality inspection, it can be put into the market.

The coating aluminium foil processing technology has certain technical difficulties and production requirements, and each link needs to be strictly controlled to ensure the uniformity, adhesion and durability of the coating. At the same time, in response to different needs, the coating formula and process parameters also need to be optimized to meet the use requirements in different fields.

Coated aluminum foil is widely used in food packaging, pharmaceutical packaging, building materials, electronic products, aerospace and other fields. It can provide excellent moisture resistance, corrosion resistance, heat insulation, light isolation, anti-skid and other functions, improving the performance and performance of various products. Extended service life provides important protection.

CLASSIFICATIONS

Coated aluminium foil is a product that is coated on the surface of aluminum foil and can be classified according to different coating materials and uses. Generally speaking, coated aluminum foil can be mainly divided into the following categories:

1. Polymer-coated aluminum foil: This type of coated aluminium foil is mainly coated with a layer of polymer material on the surface of the aluminum foil. Common polymer materials include polyethylene, polypropylene, polyester, etc. Polymer-coated aluminum foil is mainly used in the packaging industry and can be used in food packaging, pharmaceutical packaging and other fields. It has good barrier properties and preservation properties.

2. Painted aluminum foil: This kind of coated aluminum foil is painted on the surface of the aluminum foil. Common painting materials include epoxy resin, polyurethane, acrylic, etc. Paint-coated aluminum foil is mainly used in construction, furniture, electronic products and other fields to improve the corrosion resistance and decorative properties of aluminum foil.

3. Thin film coated aluminum foil: This kind of coated aluminium foil is coated with a special film material on the surface of the aluminum foil. Common film materials include PET film, OPP film, PVC film, etc. Film-coated aluminum foil is mainly used in electronic products, building materials, packaging materials and other fields to improve the mechanical strength and wear resistance of aluminum foil.

4. Adhesive coated aluminum foil: This coated aluminium foil is coated with a layer of adhesive on the surface of the aluminum foil. Common adhesives include polyurethane adhesives, hot melt adhesives, etc. Adhesive-coated aluminium foil is mainly used in packaging, building materials and other fields to improve the bonding and sealing properties of aluminum foil.

The above are some common classifications of coated aluminum foil. Different coating materials and uses determine the characteristics and application range of coated aluminum foil. With the continuous advancement of science and technology, the varieties and application fields of coated aluminum foil will continue to expand and improve, providing more solutions for various industries.

Applications

Coated aluminium foil is a product that is coated with a layer of different materials on the surface of aluminum foil. It has the excellent properties of aluminum foil and adds the characteristics of other materials, so it has a wide range of uses in various fields. Here are some of the main uses of coated aluminum foil:

1. Food packaging: Coated aluminum foil is usually used for food packaging, including chocolate, cheese, coffee, milk powder, etc. Due to its ability to isolate oxygen, moisture and light, it can extend the shelf life of food and maintain its freshness and taste.

2. Pharmaceutical packaging: Coated aluminium foil is also widely used in the field of pharmaceutical packaging, such as pharmaceutical packaging, medical device packaging, etc. It can effectively isolate water vapor, oxygen and ultraviolet rays, protecting the quality and stability of drugs and medical devices.

3. Insulation materials: Since coated aluminum foil has excellent thermal conductivity and insulation properties, it can be used as insulation materials, such as in construction, automobiles, electronic products and other fields. It can effectively insulate and block external temperature changes, and play the role of heat preservation and insulation.

4. Anti-corrosion packaging: In the chemical industry, coated aluminum foil can be used for anti-corrosion packaging, such as for the packaging of coated items such as chemicals, pesticides, paints, etc. It can effectively block the penetration of chemicals and gases and protect packaged items from erosion.

5. Pharmaceutical dressings: Coated aluminium foil can also be used in the field of pharmaceutical dressings, such as medical dressings, dressing sheets, etc. It can effectively prevent bacterial infection and external pollution, protect wounds and promote wound healing.

6. Industrial materials: In the industrial production process, coated aluminum foil can also be used as an important industrial material, such as in electroplating, painting, heat treatment and other fields. It can play a role in protection, reflection, conduction, etc., and improve production efficiency and product quality.

To sum up, coated aluminum foil has a wide range of uses, including food packaging, medical packaging, insulation materials, anti-corrosion packaging, pharmaceutical dressings, industrial materials and other fields, providing convenience and security to all walks of life. With the continuous development of technology and the deepening of application, coated aluminium foil will have broader application prospects in the future.

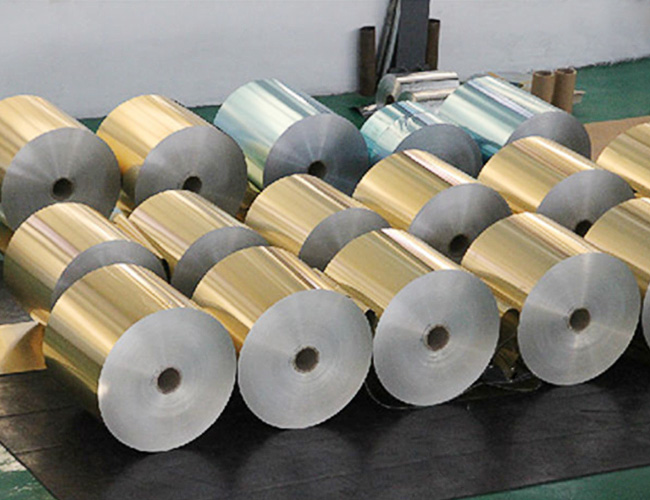

Shipping Package

Aluminum foil product meet the export standard.free-fumigated wooden case is adopted to products from damage during the delivery.there are two kinds of packaging .which is suspension packaging or Horizontal packaging. customers can choose either of them for their convenience .basically ,1x20" container can load 18-22tons. and 20-24tons in 1x40" container.Each wooden case weight from 0.5MT-1MT,upto customer's request.