Product introduction

The term “8011 aluminum foil jumbo roll” refers to a roll of aluminum foil made from 8011 alloy, a popular aluminum alloy commonly used in a variety of applications, including packaging and food containers.

Alloy 8011: 8011 is a typical aluminum alloy and belongs to the 8xxx series. It is known for its excellent performance in packaging and food-related applications. The alloy is characterized by high tensile strength, good elongation and excellent moisture, light and gas barrier properties.

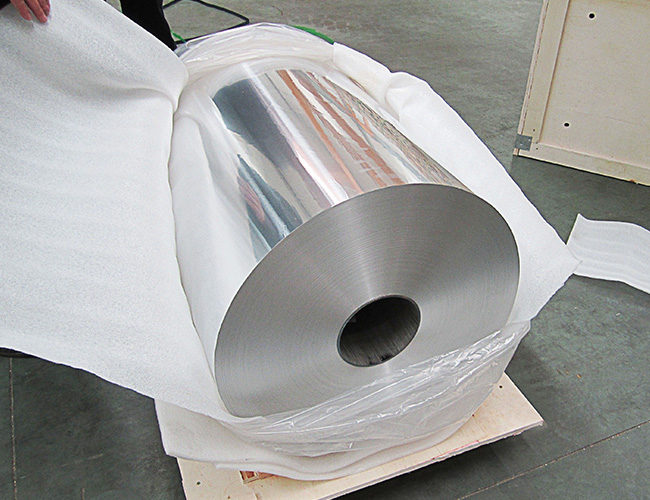

Jumbo Rolls: Jumbo rolls of aluminum foil are large, continuous rolls of aluminum foil wrapped around a core. These rolls are commonly used by manufacturers and converters to produce foils or rolls of various sizes for packaging purposes. Large rolls facilitate mass production.

8011 Aluminum foil jumbo roll for making foil container/foil tray/foil platter, Our container foil jumbo roll is superior household material for packaging which features resistance to water and oil, isolation to light and conductivity of heat. It is environmental friendly and is reusable. It can be reused and can isolate light and conduct heat. Because of these features, it is widely used in the food packaging industry.

Specifications

Temper: 8011-O

Thickness: 0.01~0.2mm (0.015mm recommended)

Width: 280/290/300/450/600mm

ID: 76/152mm, 75/150mm, 3’’/6’’

Note: no finished products (small rolls in boxes)

Advantage

8011 Aluminium Foil Paper Jumbo Rolls thickness tolerance could keep within +/-3%,which made the foils in the same thickness but also with more longer meters. however,the common supplier can only keep at 5%.

8011 Aluminium Foil Properties:

- High plasticity and corrosion resistance

- Elevctrical conductivity and thermal conductivity

- Gas welding,hydrogen welding and resistance welding

- Under various pressure processing and extension,bending

8011 Aluminum Foil Chemical Composition:

| Alloy No. | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | |

| 8011 | 0.50 – 0.90 | 0.60 – 1 | ≤ 0.10 | ≤ 0.20 | ≤ 0.050 | ≤ 0.050 | ≤ 0.10 | ≤ 0.080 | —— | REMAIN | |

Hot Sale 8011 Aluminum Foil

| 11111 | Type | Temper | Thickness | Width | Length |

| 8011 Household Foil | Bare, Mill Finish | O ( HO ), H12, H14, H16, H18, H22, H24, H26, H28, H34, H111 | 0.01-0.2mm | 300-1100mm | coil |

| 8011 Container Foil | Bare, Mill Finish | H22 H24 | 0.01-0.2mm | 200-1100mm | coil |

| 8011 packaging foil | Bare, Mill Finish | O H22 H24 | 0.018-0.2mm | 100-1600mm | coil |

| 8011 Pharmaceutical Foil | Bare, Mill Finish | H14 H18 | 0.018-0.2mm | 100-1600mm | coil |

8011 Aluminum Foil Application And Use:

Household:

food container, duct tubes, burner guard etc

Commerial:

white wine cap, yogert lid, milk cap, yogert etc

- Food Use Preparation: Aluminum foil is “dual-ovenable” and can be used in both convection and fanassisted ovens. A popular use of foil is to cover thinner sections of poultry and meat to prevent overcooking. The USDA also provides recommendations on limited uses of aluminum foil in microwave ovens.

- Insulation: Aluminum foil is 88 percent reflective and is widely used for thermal insulation, heat exchanges and cable liners. Foil-backed building insulation not only reflects heat, also provides a protective vapor barrier.

- Electronics: Foil in electrical capacitors provides compact storage for electric charges. If the foil surface istreated, the oxide coating works as an insulator. Aluminum foil capacitors are commonly found in electrical equipment, including television sets and computers.

- Geochemical Sampling: Aluminum foil is used by geochemists to protect rock samples. Foil provides a seal from organic solvents and does not taint the samples as they are transported from

the field to the lab. - Art and Decoration: Anodizing aluminum foil creates an oxide layer on the aluminum surface that can accept colored dyes or metallic salts. Through this technique, aluminum is used to created inexpensive, brightly colored foils.

8011 Aluminum Foil For Pharma Packaging

8011 aluminum foil is an aluminum alloy commonly used in pharmaceutical packaging. Has excellent corrosion resistance, high ductility, and good thermal and electrical conductivity.

8011 Pharmaceutical packaging Materials that protect against moisture, light, oxygen, and other environmental factors to ensure drug stability and efficacy. Aluminum foil is the material of choice for pharmaceutical blister packaging due to its barrier properties and compatibility with various sealing methods.

The main characteristics of 8011 aluminum foil for pharmaceutical packaging:

Barrier properties: 8011 aluminum foil has excellent barrier properties to protect pharmaceutical products from moisture, light, gas and other external factors that can degrade the quality of pharmaceutical products.

Flexibility: Aluminum foil is highly flexible and can be easily formed into various shapes of blister packaging. This flexibility allows it to fit snugly around products, providing a snug fit and enhancing the protective barrier.

Heat-sealability: Aluminum foil can be heat-sealed to a variety of substrates for a secure and tamper-resistant packaging solution. This is critical to maintaining the integrity of the drug product.

Compatibility: Aluminum foil is compatible with a variety of printing and labeling technologies, making it easy to apply branding, information and instructions to packaging.

Non-toxic: Aluminum foil is non-toxic and safe for direct contact with pharmaceuticals, ensuring no contamination or adverse interactions.

Cold Formability: Cold formability refers to the ability of an aluminum foil to be formed at room temperature without losing its barrier properties. 8011 aluminum foil is typically used for cold forming blister packs, where the foil is pressed into a mold at room temperature.

Thickness range: 8011 aluminum foil is available in a variety of thicknesses, which can be customized according to specific packaging requirements and the sensitivity of the packaged drug.

Packing

- Package: Wooden case

- Standard Wooden case specification: Length*Width*Hight=1.4m*1.3m*0.8m

- Once needed,wooden case dimension could be redesigned as required.

- Per wooden case Gross Weight scale: 500-700KG Net Weight: 450-650KG

- Remark: For special packaging requirements, corresponding shall be added accordingly.